TitanCast™ Was Tested in the National Research Council of Canada

- CIM Media

- Dec 12, 2019

- 1 min read

Updated: Mar 24, 2021

TitanCast™ is a compound material with titanium carbide metallurgically bonded in high chrome white iron, high manganese steel or mild steel by the Self-propagating high temperature synthesis (SHS) process. The extra fine titanium carbide particles are generated in situ and provide wear protection of high-impact erosion and low - stress abrasion.

TitanCast™ is developed for medium to heavy load applications and the combination of high hardness of the titanium carbide and high toughness of the base materials make the wear products suitable for high impact applications.

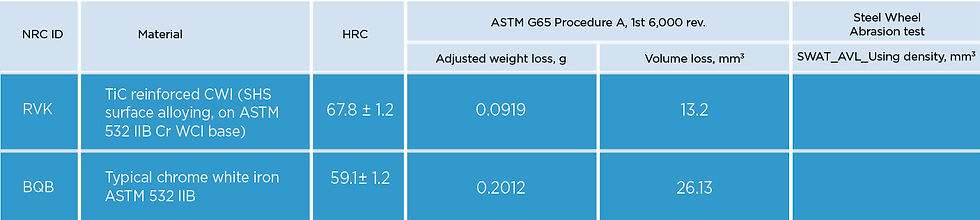

CIM TitanCast™ was tested in the National Research Council of Canada in June 2020. The wear tests include ASTM G65 and Steel Wheel Abrasion Test (SWAT). The wear scar of G65 was analyzed, and it showed that the carbide particles and the base are metallurgically bonded; the extra fine titanium carbide stands out from the base; the hard carbide particles and tough base materials are combined to protect the parts from high impact abrasion.

The wear test results are showed that the metal loss of the TitanCast™ composite material is half of the ordinary chrome white iron ASTM A532 IIB. CIM is looking for opportunities to apply the technology to the mining, energy and construction industries.

Comments